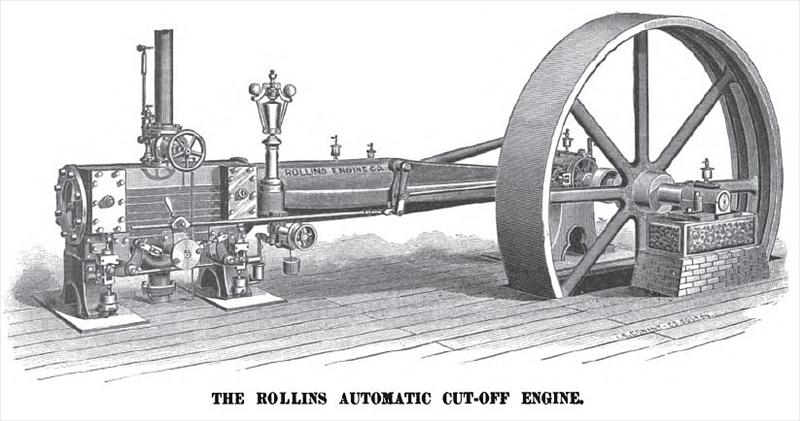

The engine was built in 1898 by the Rollins Engine Co. of Nashua, NH for the D. B. Gurney Company. The engine ran until 1945 and has been well taken care of since. With the engine came many original tools and spare parts.

What’s next? The volunteers are still working on a long-term plan for the engine. For starters, we’ll begin to clean and lube. And we need to accurately survey the original foundation bolts and elevations at Gurney to aid reinstallation later.

Here is Ernie’s description of the moving process:

Disassembly

- Remove the small parts, governor with linkage, main bearing caps, oilers, eccentric rods and valve links etc.

- Turn engine to a little past top dead center and unscrew the piston rod from the cross head.

- Disconnect the connecting rod from the crank pin and push the cross head and piston rod out of the bed frame using a porta power.

- Move the flywheel so the halves are horizontal. Support the bottom half with timbers across the flywheel pit and unbolt the 2 halves.

- Unbolt the bed frame and outer main bearing from their foundations.

Crane

- Lift off the top half of the flywheel.

- Lift out the crankshaft.

- Lift the bottom half of the flywheel off of its supporting timbers and out of the flywheel pit.

- Lift the outer main bearing from the top of its pedestal/foundation.

- Remove the exhaust pipe from the bottom of the cylinder.

- Lift the bed frame and cylinder. Once these are away from the pit we will separate the bed frame and the cylinder.

- Lift the exhaust pipe out of the pit.

All sounds easy right? It took all of us about 8 hours yesterday. What made it easier was that all the monster wrenches that came from Rollins with the engine are still with the engine, along with a 10 foot long piece of pipe. We also have the original universal flywheel jacking bar which will work on our other big engines when one stops in the wrong position. It has a neat toggle link that grabs the flywheel rim on a long wooden handle.