The SS Nobska had a 202 foot long, 36 foot wide, steel hull, and weighed 1082 tons when loaded. During the summer it carried 1960 passengers, and 230 passengers during the winter.

The Nobsk’s two Babcock and Wilcox Sectional Header Water Tube boilers generated steam at 200 lbs./sq. in. The boilers were originally designed to burn coal, but were later converted to burn oil. Each boiler had a Coppus Engineering Turbo Forced-Draft Blower.

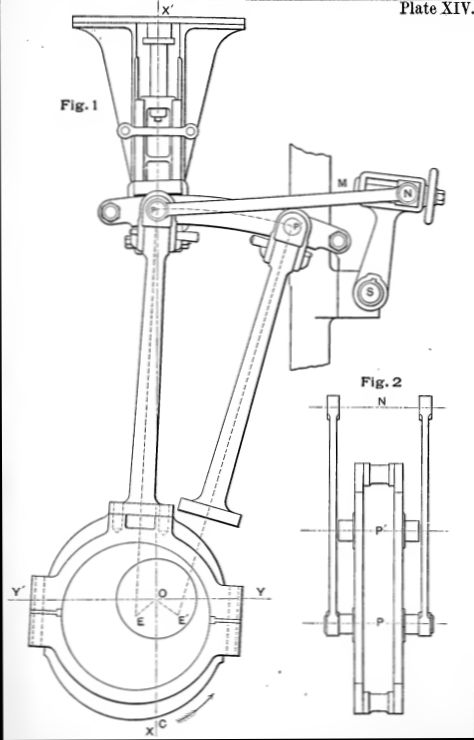

The four-cylinder, triple-expansion, double-acting, open-frame steam engine has cylinder diameters of 16″, 26″, and 30″, with a stroke of 24″, and made 1,200 Indicated HP @ 200 RPM. This engine has two low-pressure cylinders according to the the Yarrow-Schlick-Tweedy balancing system. Dividing the low-pressure expansion between two cylinders at each end of the engine makes the engine smaller, the crankshaft is better balanced, and results in a smoother, faster-responding engine with less vibration. The engine has one piston valve for the high-pressure cylinder, and two piston valves for each of the intermediate-pressure and low-pressure cylinders. The engine has Stephenson Valve Gear to allow for reversing. The valve gear has only three possible positions; full-gear forward, full-gear backing, and mid-gear. Gag screws on the valve linkage allows the cutoff to be independently adjusted for each cylinder to optimize operation. A steam piston is used to shift the valve linkage from the full-gear forward to the full-gear backing position to reverse the engine. The bearings were oiled by a gravity fed system and supplemented every 15-20 minutes by hand oiling. The steam engine directly drove an 8-foot diameter four-bladed left-handed propeller, allowing the SS Nobska to cruise at 14 knots. The left-handed propeller made docking easier for the Nobska.

The SS Nobska was in regular service until September 18, 1973. The last trips were under the command of Captain Richard Faria and Chief Engineer Joseph Dawicki. In June 1975 it was sold and converted to a floating restaurant in Baltimore, MD. The restaurant failed after a few years and the ship sat derelict until the Friends of the Nobska (later the New England Steamship Foundation) bought the ship in 1988. In April 1996 the Nobska was moved to the drydock in the old Charlestown Navy Yard for restoration. In August the steam engine was removed. The 13.5 ton engine was trucked to the automotive shop at the Greater New Bedford Regional Vocational Technical High School at no charge by J.P. Noonan of West Bridgewater. Nobska’s last Chief Engineer, Joseph Dawicki, supervised the work on the engine. The ship restoration fell through after years of significant fund raising and restoration, and the hull was scrapped in 2006.

Fortunately the steam engine was stored instead of also being scrapped, and donated to the NEWSM in 2024. The museum plans to expand the Steam Building to house the engine and restore the engine to operation. Fund raising information will follow.

Some steam engine math…

A triple-expansion steam engine expands the steam three times in order to extract nearly all of the energy contained in the steam. The steam pressure from the boilers was 200 lbs./sq. in. Since the diameter of the first piston is 16″ the surface area of the piston is 201.06 sq. in. The force on the first piston from the steam is 40,212 lbs. To keep the engine balanced and vibration free the force on the pistons needs to be the same. The second piston’s diameter is 26″, so the surface area of the piston is 530.9 sq. in. To create the same force as on the first piston the exhaust steam pressure from the first piston that acts on the second piston must be 76 lbs./sq. This steam engine has two 30″ third pistons with a combined surface area of 1,413,8 sq. in. Again, to have the same force as on the first and second pistons the exhaust steam pressure from the second piston acting on the third pistons must be 28 lbs./sq. That means that the exhaust steam pressure from a piston is about 37% of the inlet steam pressure, and the exhaust steam pressure from the pair of third pistons would be only about 10 lbs./sq. The 10 lbs./sq. exhaust pressure from the steam engine is only 5% of the original boiler pressure, so that means nearly all of the energy from the steam was extracted by the steam engine. It is interesting to note that a steam engine can make maximum torque when stopped and the crankshaft throw is perpendicular to the connecting rod. This engine has a stroke of 24″ so the crankshaft throws are 1 foot. With 40,212 lbs. of force from a piston the torque would be 40,212 lb · ft. For comparison a typical car engine might make 300 lb · ft of torque.

External Links:

There is a 1950s documentary film on the Nobska on YouTube. The video of the engine starts at 5:26.

The Wikipedia explanation of Triple-Expansion Steam Engines.