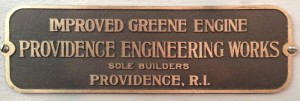

The Improved Greene Engine Automatic Cut-Off engine was designed by Noble Tuckerman Greene and built by the Providence Steam Engine Company, 373 South Main St., Providence, RI. This 17″ X 36″ 150 Horse Power engine was installed in the Rhode Island Cardboard Company, 163 Exchange St, Pawtucket, RI in 1897. It was used to manufacture detachable shirt collars, wedding stationary, stock for art calenders and other cardboard products. When the engine was last run in 1919 it was completely serviced by the Providence Engineering Works. A copper plate “cookie” was installed in the steam line which protected the internal engine parts from damage. The NEWSM has many of the original manufacturing drawings for this engine.

The Greene engine uses the “drop cut-off” or “detachable valve-gear” invented by Frederick E. Sickels in 1841. The grid-iron admission valves were designed by young Robert Henry Thurston immediately after he graduated from Brown University. Providence Steam Engine Company owned the Sickels patent and they sued Corliss Steam Engine Co. when they infringed the Sickels patent. Corliss counter sued and spent over $106,000 in legal costs, and finally won because of a minor omission in the Sickels patent. Greene was restrained from building his own engine. When the patent expired in 1869, Providence Steam Engine Company built Greene engines again, building a total of 317. There are three Greene engines known to exist, ours, a slightly smaller one at CAMA in Kent, CT, and a small 12″x30″ one in a private collection.

The Greene engine uses the “drop cut-off” or “detachable valve-gear” invented by Frederick E. Sickels in 1841. The grid-iron admission valves were designed by young Robert Henry Thurston immediately after he graduated from Brown University. Providence Steam Engine Company owned the Sickels patent and they sued Corliss Steam Engine Co. when they infringed the Sickels patent. Corliss counter sued and spent over $106,000 in legal costs, and finally won because of a minor omission in the Sickels patent. Greene was restrained from building his own engine. When the patent expired in 1869, Providence Steam Engine Company built Greene engines again, building a total of 317. There are three Greene engines known to exist, ours, a slightly smaller one at CAMA in Kent, CT, and a small 12″x30″ one in a private collection.

Robert Merriam explains the Greene valve linkage in this Fred Tanner film.

Below is an indicator diagram taken on the Greene engine. The steam engine indicator is a device that is similar to an oscilloscope but is entirely mechanical. The X axis of the diagram corresponds to the position of the piston during the stroke. The Y axis corresponds to the pressure in the cylinder.

Since the engine was running without a load the steam valve was closed very early in the stroke. The point where the steam valve is closed is called cutoff and is controlled by the governor. After the steam valve closes the steam expands pushing the piston down the cylinder. Using the steam expansively is the only way to get good efficiency from a steam engine. At the end of the stroke the exhaust valve opens releasing any remaining steam pressure. The pressure in the cylinder is zero until the piston is nearly back to the beginning of the stroke. At this point the exhaust valve closes and the air in the cylinder is compressed. Compression helps make the engine run smoothly.

The engine was restored by the “Greene Team” that consisted of Jeffrey R. Berry, Raymond Coleman, J. Stuart Edwards, Harold C. Foster, Richard B. Hanson, Terrance K. Jones, Ed Mcgowan, Nancy A. Merriam, Paul A. Merriam, Robert W. Merriam, Thomas Patterson, Robert Phillips, Rolf Richter, Christopher Rooney, Michael G. Thompson, and Louis O. Vertefeuille. Dave Moultrop of South County Steel moved the 17,000 pounds of engine from Pawtucket to the museum. Cardi Corporation of Warwick, RI donated the concrete that was used to build the foundation for the engine. Phil-Weld of Coventry, RI and Trawl Works, Inc. of Narragansett, RI donated rigging supplies.