From the Providence Directory, 1889

Shipman Engine Co. produced packaged engines in Boston, Massachusetts.

From the 1882 Industries and Wealth:

A. T. CROSS, Inventor and Sole Manufacturer of the Cross Pen and Pencil Cases, Stylographic and Fountain Pens, Agent for the Shipman Automatic Steam-engines and Shipman Steam Launches, Office and Factory, No. 53 Warren Street. — The Shipman Automatic Steam-engine is one of the most perfect pieces of mechanism on the face of the earth. They are manufactured by the Shipman Engine Export Company of Boston, and are sold in Providence by Mr. A. T. Cross, as agent for the State of Rhode Island, with headquarters at No. 53 Warren Street. These engines are made from 1 to 8 horse power, and are simple, efficient and economical. They are desirable above all other small power engines, because you can be your own engineer and fireman; they are economical in the use of fuel, automatic in their water and fuel supply, and consume only the amount of fuel required for the power taken. They put out their own fire and relight again when more power is required, and the moment the work is done the fuel expense stops. Its fuel has no dust, and the fire never has to be ‘drawn’. If you have only one hour’s work to do, you can get up a steam pressure of one hundred pounds, do the hour’s work, put out the fire, and the consumption of fuel will not exceed one hour and seven or ten minutes, at a cost not to exceed three or five cents per horse power. They are designed especially to operate presses for printers and lithographers, air fans and ventilators for storekeepers and restauranteurs, pumps and churns for farmers, sewing machines for dressmakers, mixers and freezers for confectioners, folders and trimmers for bookbinders, washing and other machines for laundries, blowers and lathes for blacksmiths, dynamos for electricians, lathes and planers for machanics and machinists, pumps and sprinklers for florists and gardners, coffee roasters and mills for grocers, and are especially adapted for boot and shoe makers, tailors, stationers, bakers, dentists, painters, plumbers, dyers, jewelers, brass-finishers, assayers, carpet-cleaners, carriage-builders, furniture-makers, boxmakers, boatmen and yachtsmen. The ‘Little Giant’ engine for rowboats and launches surpasses anything of the kind ever made. It is very rugged in construction, compactly built, and is proportioned for hard work and high duty. Piston has spring self-adjusting packing rings; steam and exhaust ports are ample in size to prevent wiredrawing of steam; ports are cut to template to ensure agreement, and cutoff is sharp and rapid in action. Steam chest being as long as cylinder the ports are short and straight, reducing clearance to practically nothing. Piston rod is steel, with solid butt fastened to crank box with turned bolts and profuse lubrication of the crank pin and bearing. This result is attained by turning a suitable groove in the outside of crank disc, a passage connects the groove with crank pin; and the oil that may drop from main bearing is collected by the groove and driven by centrifugal force to the crank pin bearing. The Shipman steam launches are designed and built to secure the greatest speed with safety. They are made of the best material and by skilled workmen. They are furnished with brass chocks, cleats, rowlocks and stem-bands, two oars, a boathook, two lockers, one on each side of boat or in the stern, with brass locks and hinges, anchor, steering-wheel, shoe, rudder, rudder-shaft and tiller complete. The last four articles are made of brass when boat is fitted for use in salt water, and they may be made of iron when boat is for use in fresh water. Mr. Cross, the agent for Rhode Island, is best known as the inventor and manufacturer of the Cross pen and pencil cases, stylographic and fountain pens. He has been engaged in that industry for a period of thirty years and his productions go to all parts of the world. The Cross stylographic pen is recognized the world over as the king of writing instruments, and are now sold by Messrs. Greenough, Hopkins & Cushing, at No. 168 Devonshire Street, Boston. Mr. Cross is a native of England, a resident of this city for forty years, and honored and esteemed for his genius as an inventor and his enterprise and reliability as a business man.

From the 1891 Manufacturer and Builder:

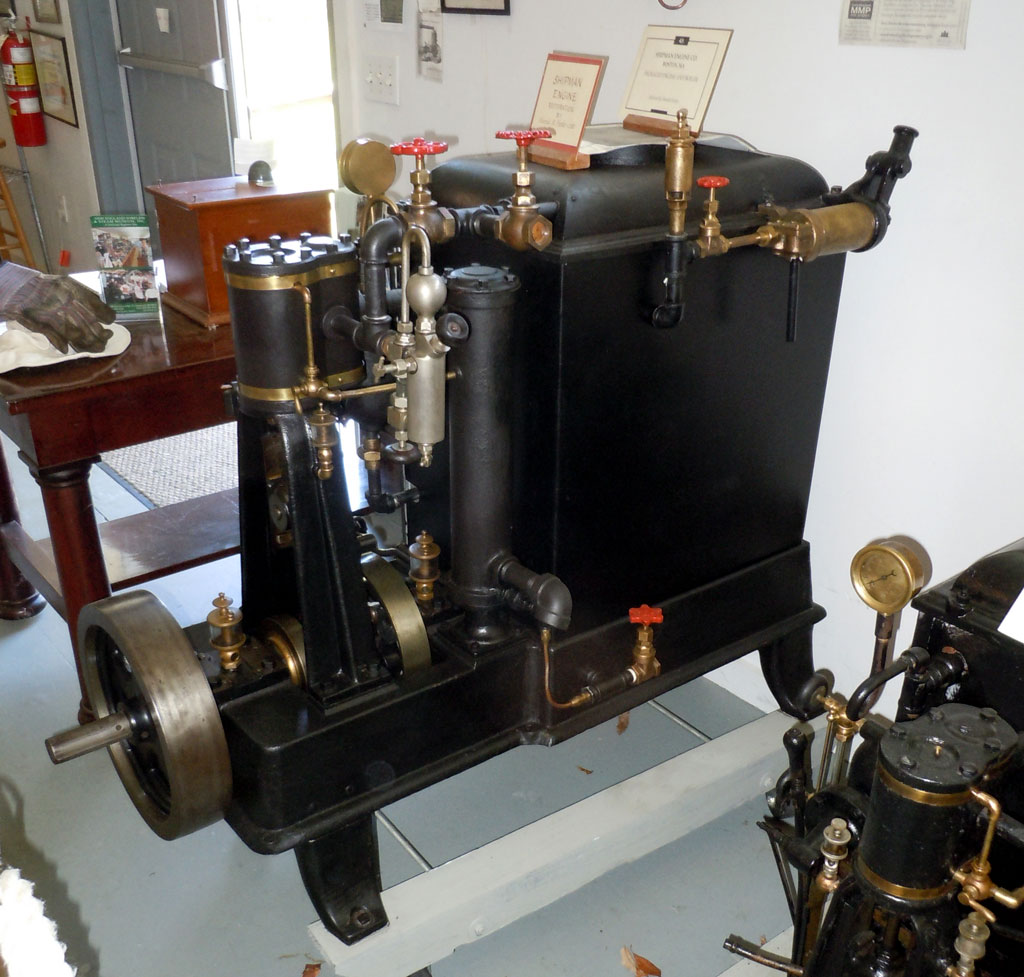

The Shipman Engine

The engine known by this name has been made the subject of so many improvements, that in its present form it is a vastly different machine from that of five or more years ago. In a general way it may be defined as an automatic, petroleum-burning steam engine, designed for almost every form of service where moderate powers are required; and one of its essential features of merit consists of its entirely automatic action, in virtue of which, after steam has once been generated in the boiler, the machine requires no further attention on the part of the operator, beyond the opening and closing of the steam valve in starting and stopping it. The mechanism of the engine regulates the fire, speed and water supply without outside intervention.

Various types of this engine are built, simple and compound, according to the nature of the work required of them; and they are built either upon the same frame as the boiler or on a separate frame, as may be found expedient in setting up the machine. The boiler is of the water-tube pattern, composed of a large number of tubes of about 13 inches long, which are screwed into a flat, oblong chamber at one end and closed at the other. The water is supplied in these tubes, which are heated by external fire. The petroleum used as a fuel is sprayed into the furnace by means of an atomizing device and as the spray of steam and oil vapor enters the furnace, it is ignited by a flame maintained for the purpose, and the flames caused by the combustion play about and among the water tubes, effecting the very rapid generation of steam. The petroleum is supplies from a chamber below the boiler, and is sucked up as required by the atomizers. The amount of steam and petroleum used by these atomizers is regulated by a diaphragm connected to a valve in the steam pipe that supplies them.

This diaphragm is exposed to the steam pressure on the one side and is held down by a spring, loaded to a certain pressure, on the other, and moves upwards or downwards as the steam exerts more pressure on the spring, or vice versa. Its movement is conveyed to the valve by means of a rod, and it thus regulates the amount of steam passing at any moment to the atomizers. In this way the fire is made to vary inversely as the pressure in the boiler, and thus keeps the latter constant.

The petroleum is stored in a tank at any convenient distance from the motor, and is led to it through a pipe connecting with the oil tank. The water in the boiler is kept at a constant level by means of a float, connected to a valve in the suction pipe of the pump. This float is placed in a chamber, which is joined to the top and bottom of the boiler, and rises or falls with the level of the water. The movement is conveyed, through a stuffing-box, and by means of levers, to the valve in the suction pipe, which it opens of closes as the water level changes.

The speed of the engine is kept regular by means of a governor, which works directly on the eccentric; and the lubricating of all journals, cylinders and slides is preformed by the ordinary sight-feed lubricators and cups, except that of the crank pin, which is effected by means of a centrifugal oiler attached to the crank disk. It may be seen from the foregoing that when once steam is up, the fires, the water supply, the oiling, and the speed of the engine require no further attention. But when first starting, a sufficient pressure is required in the boiler to work the atomizers, and for this a hand air-pump is provided. A few strokes of this pump will suffice to start the fires, and it is only necessary to pump slowly for five minutes to raise sufficient pressure of steam to keep the going, fifteen minutes is all being required to get steam up to 100 pounds per square inch.

The Shipman engine is built on sizes from 1 up to 22 horse-power, and is adapted to every form of service for which engines of moderate power are required. They are specially servicable, however, for boats, running elevators, for printers, for pumping and electric lighting service. They are furnished complete, with all attachments, ready for service. The oil used in connection with these engines is 110 to 115 fire-test, and insurance is not affected by their use. The engines are compact, readily understood, take up very little space, do not require strong foundations, and can be run by anyone after careful perusal of instructions which are sent with each shipment.

The Shipman engine shown in our picture is a stationary engine of what is called by the makers the Boston model, which embodies all of the features described in what has preceded. These engines are built by the Shipman Engine Export Co., 326 Summer street, Boston. The New York office is located at 114 Liberty street.